CGPT —

EFFECT OF OPEN-AIR FIRE ON STEEL

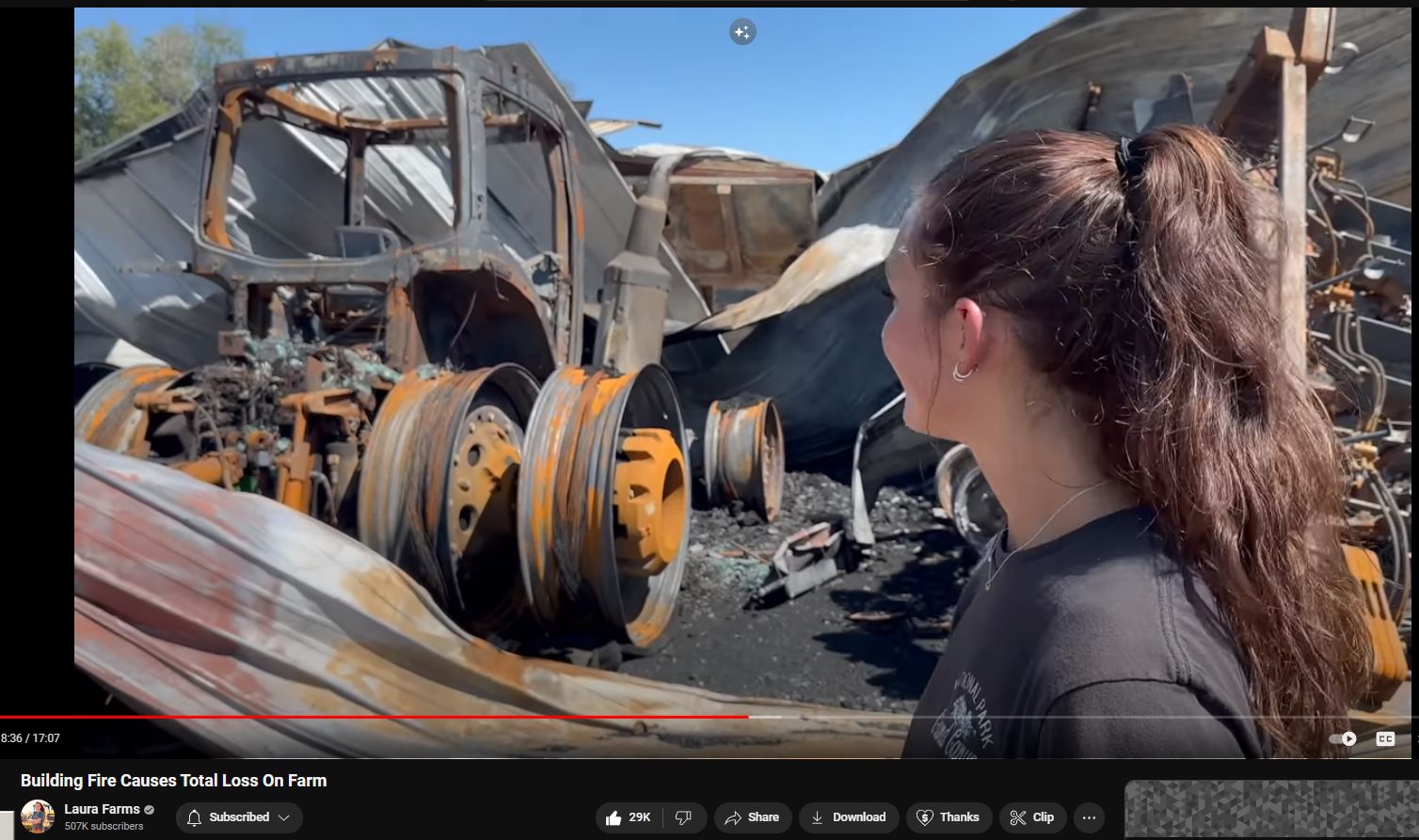

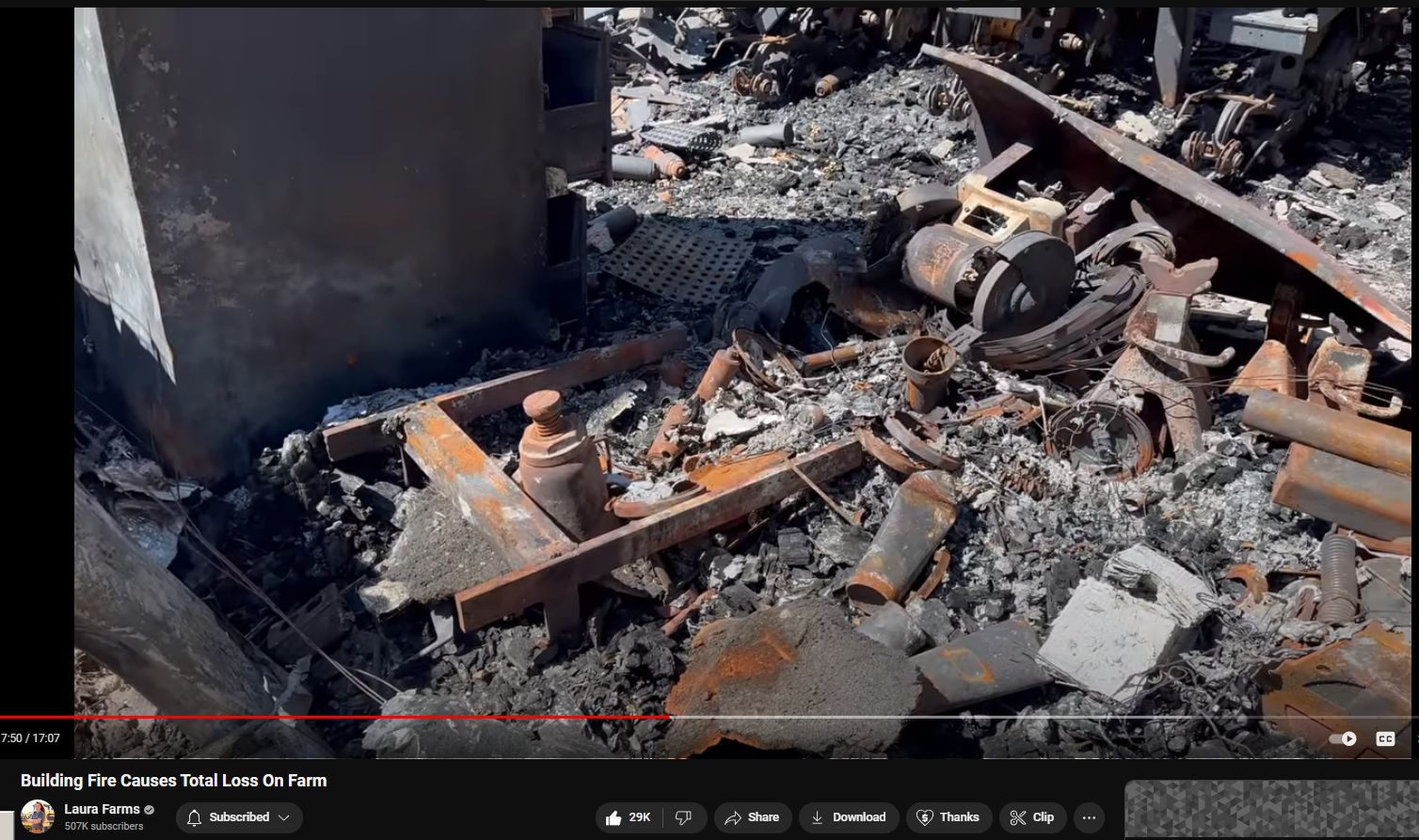

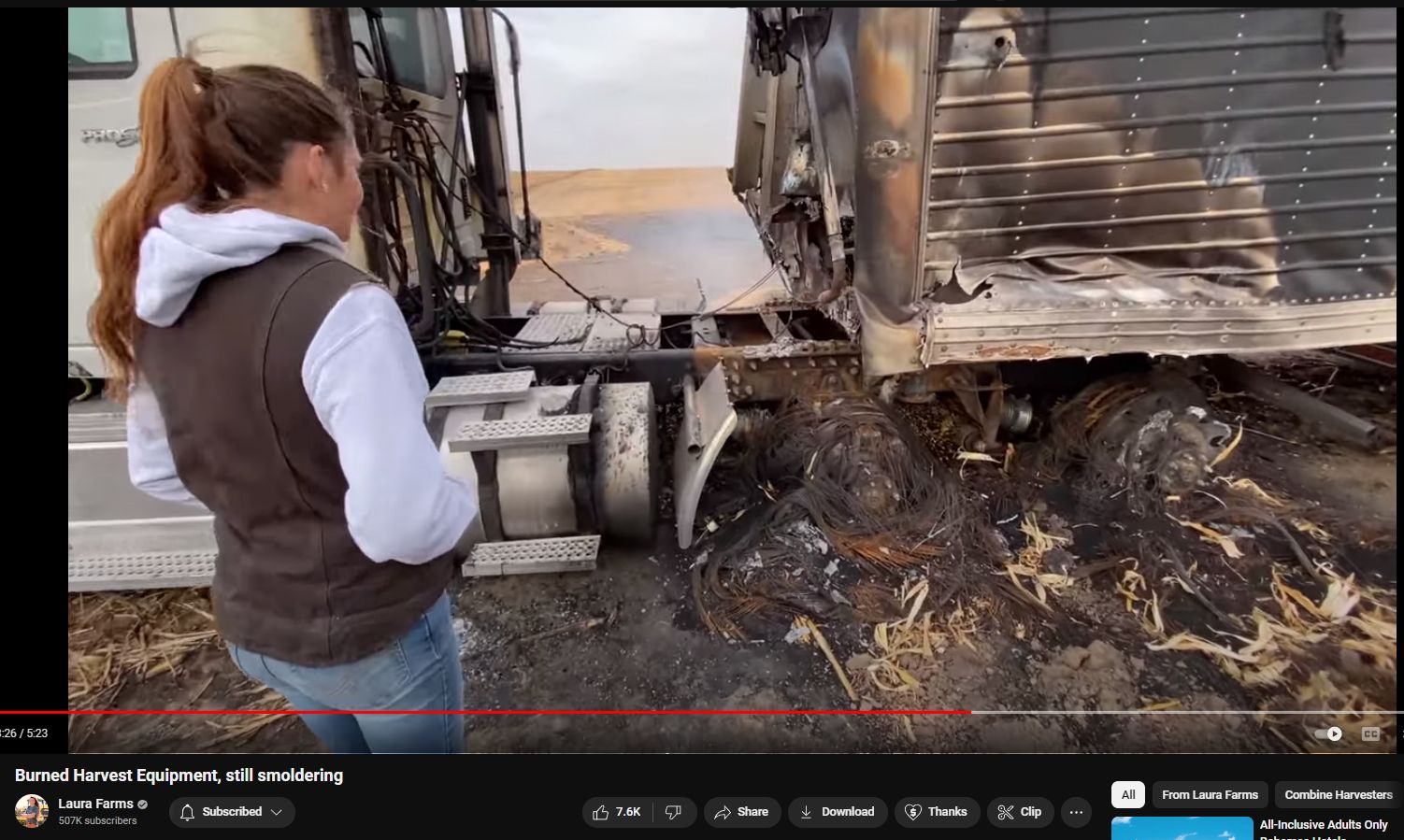

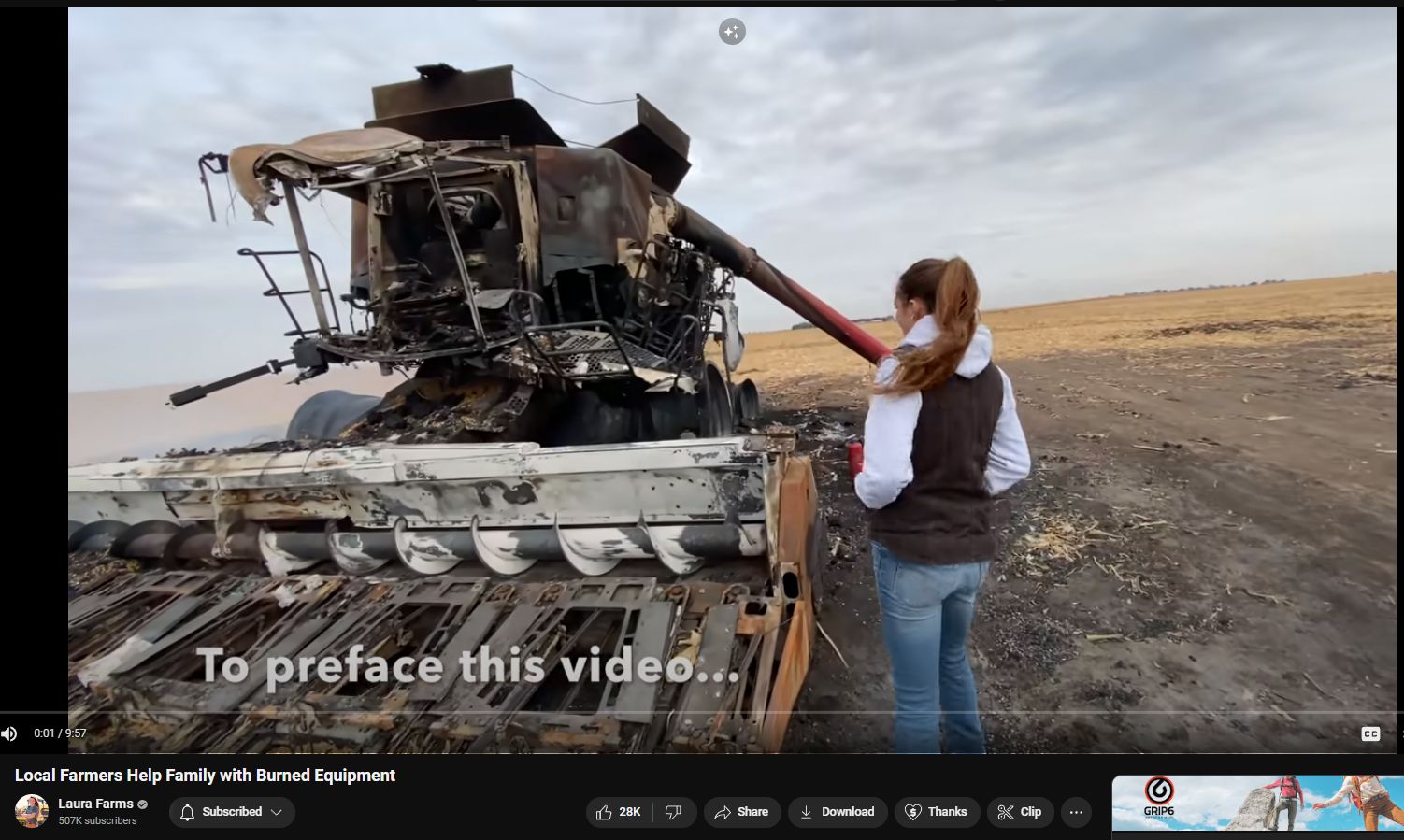

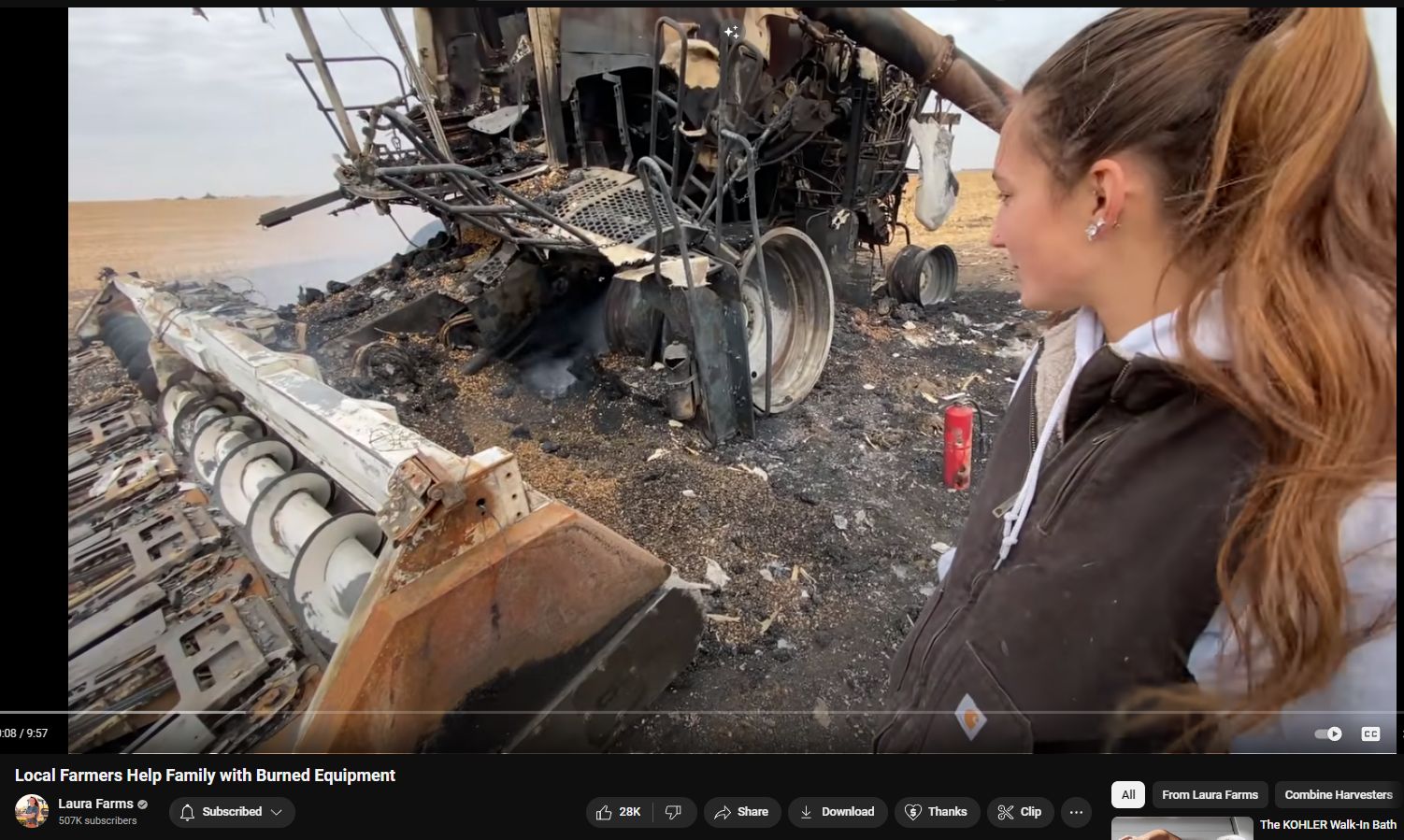

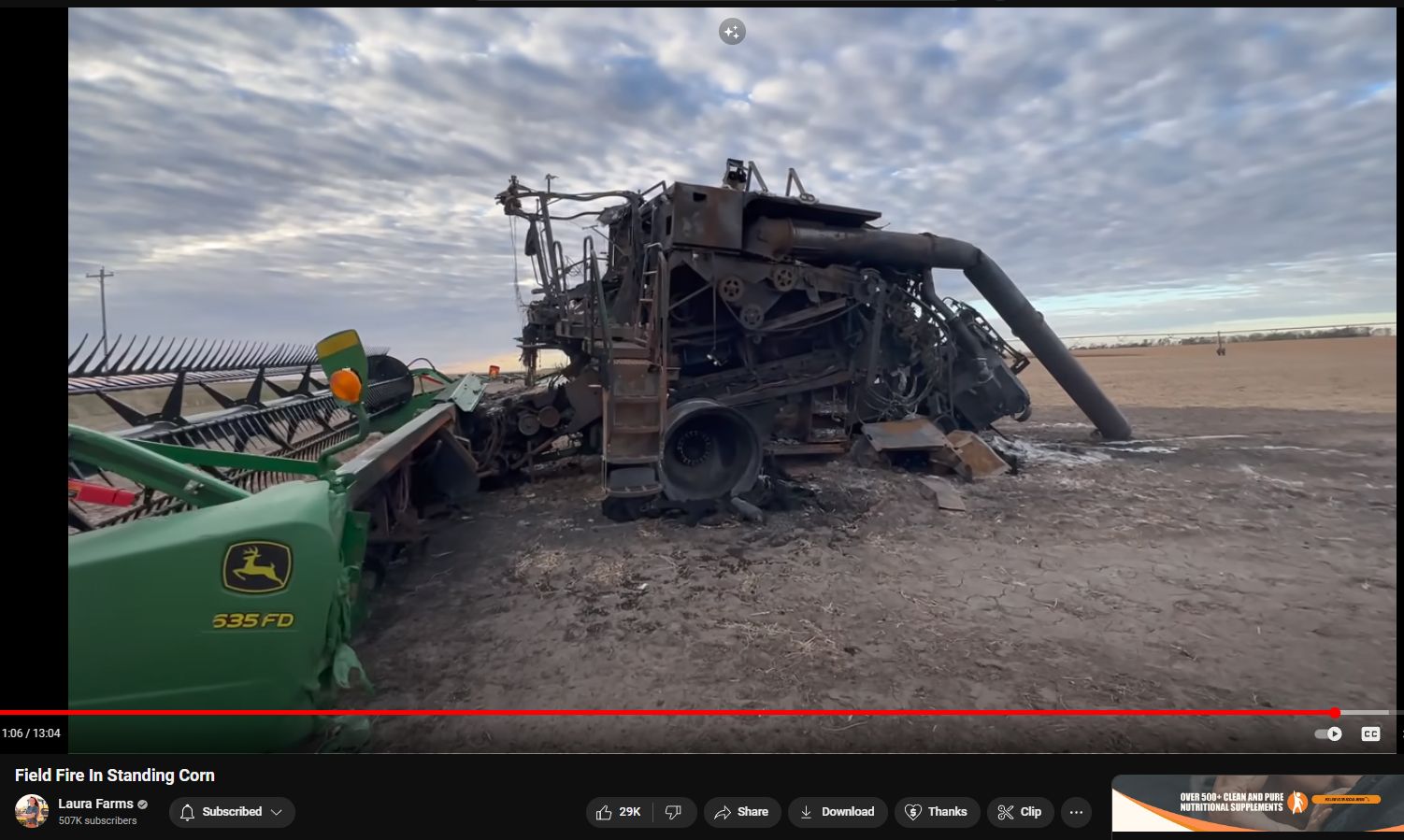

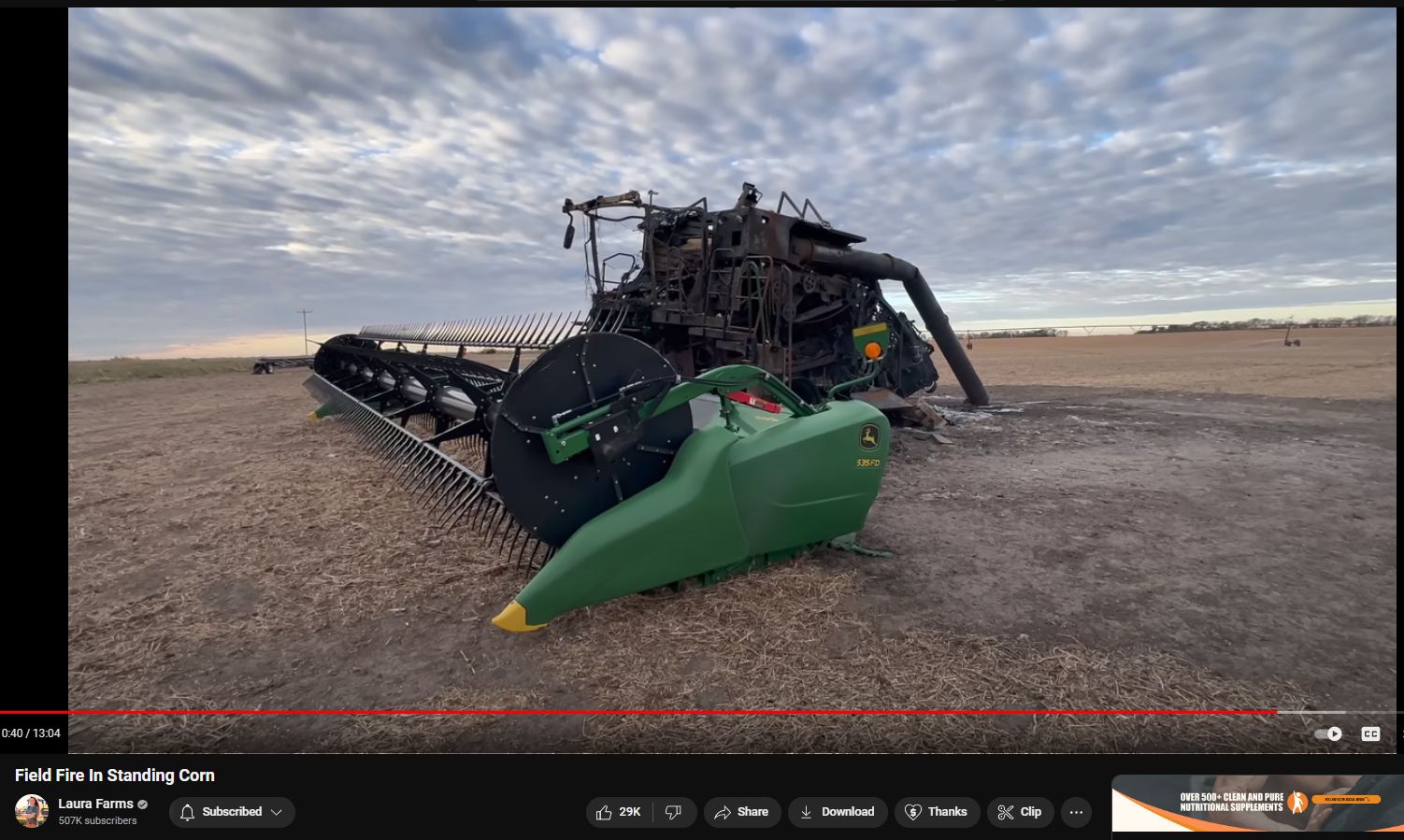

Catalogging the strange destructions of farm equipment. Is this another assault on food production? …that accompanies the thousands of food processing facilities that have recently “burned” similarly strangely?

It appears that the aluminum and non-steel / non-ferrous metals evaporated from heat and/or puddled. Glass is similarly affected. Ceramics appear to be powderized. Is the steel being superheated by eddy currents induced by microwave weaponry? The superheated steel then combusting nearby flammables. Just an hypothesis.

There is this recurring theme of “only dust and steel remain” at an alarmingly growing number of suspicious locations, including Lahaina, Maui, Hawaii.

Strange, the second and third videos, which show strangely “burned” farm equipment, including heavy-duty steel / aluminum grain rig / 18-wheeler trailer / grain-hopper having massive holes “melted” completely through the metal, while immediately adjacent is absolutely unburned, unbrowned, unscathed, highly-flammable corn husks, kernels and other organic debris. Hot fire was clearly not involved there; instead, an energy beam appears more likely the cause?

LAURA FARMS

https://www.youtube.com/watch?v=ZrnD1n7zw7M

https://www.youtube.com/watch?v=WTmCJGNKepk

https://www.youtube.com/watch?v=Tu0vlSWdWig

https://www.youtube.com/watch?v=0xImk4VhBXY

https://www.youtube.com/watch?v=wUkijLtEKMA

CGPT —

EDDY CURRENTS INDUCED INTO STEEL BY MICROWAVES