Every machine has an acoustic signature

Every machine has its own acoustic signature – a precise frequency that indicates whether that machine is operating at peak performance. GE engineers monitor and record these sounds to perform real-time diagnostics on airplane engines, locomotives, power turbines, and medical equipment. Musician Matthew Dear and GE Acoustics Engineer Andrew Gorton teamed up to collect and compose thousands of audio emissions from the world’s most powerful machines. The result is an original track of music titled “Drop Science.” Download the full track on our SoundCloud.

http://generalelectric.tumblr.com/post/95823877921/every-machine-has-its-own-acoustic-signature-a

The term “mechanical sonic signature” refers to the unique combination of sounds or acoustic emissions produced by mechanical systems or devices during operation. This concept is particularly relevant in fields such as engineering, acoustics, and even military applications, where identifying and analyzing the sounds from machinery can provide valuable insights into the system’s condition, performance, and identity.

Applications and Importance

– Diagnostic and Maintenance: In engineering and maintenance, analyzing the mechanical sonic signature of machinery like engines, turbines, and pumps can help in identifying wear, faults, or failures early. By monitoring changes in the acoustic emissions over time, maintenance teams can predict when a component might fail and intervene preemptively, thus preventing downtime and expensive repairs.

– Quality Control: In manufacturing, the sound produced by equipment or during the processing of materials can indicate the quality of the product or the proper functioning of machinery. Consistent sonic signatures suggest that the process is stable, while deviations might signal a problem.

– Security and Surveillance: In military and security contexts, the mechanical sonic signature of vehicles, aircraft, or ships can be used for identification and tracking. Each type of machinery has a characteristic sound profile that can be detected and analyzed to determine its type, activity, and even its specific identity in some cases.

– Environmental Monitoring: The impact of industrial or transportation-related noise on the environment can be assessed by studying the sonic signatures of different sources. This can inform policies and measures to reduce noise pollution and protect wildlife and human communities.

Techniques for Analysis

Analyzing a mechanical sonic signature involves recording the sound emitted by the device or system and then using various signal processing techniques to extract meaningful features from the audio. This can include:

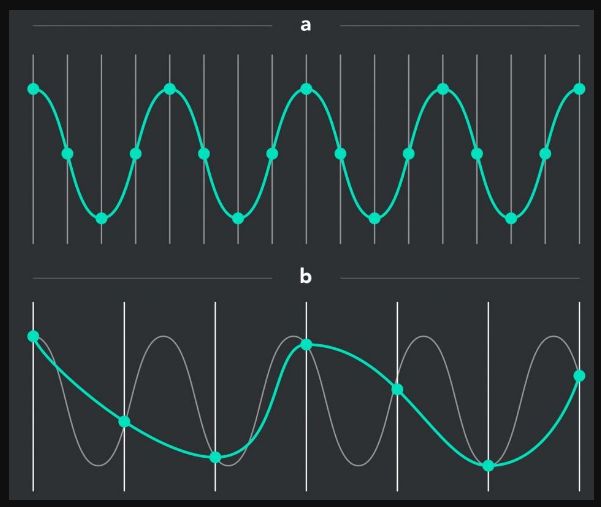

– Spectral Analysis: Examining the frequency spectrum of the sound to identify dominant frequencies, harmonics, and patterns that characterize the sonic signature.

– Time-domain Analysis: Looking at how sound amplitude changes over time to identify patterns or anomalies.

– Machine Learning: Applying algorithms that can learn to recognize patterns or anomalies in the sound data, facilitating automatic identification or diagnosis.

Challenges

While the analysis of mechanical sonic signatures offers valuable insights, there are challenges as well, such as:

– Background Noise: Distinguishing the target sound from background noise can be difficult, especially in noisy environments.

– Complex Signals: Some systems produce very complex acoustic emissions that can be hard to analyze and interpret.

– Dynamic Conditions: The operating conditions (like load, speed, or temperature) can affect the sonic signature, requiring adaptive analysis methods.

Despite these challenges, the study and application of mechanical sonic signatures continue to grow, driven by advancements in sensor technology, signal processing, and machine learning, offering new opportunities for enhancing system performance, safety, and environmental stewardship.