Drum shell bearing edges vitally affect tone and feel response of the heads / drums.

I discuss bearing edges and their affect on a drum’s performance. Let’s see if I can’t distill this topic down to the important bits.

0:00 Introduction

2:11 Bearing edge definition and purpose

6:55 Keeping it simple — two basic types of edges

9:50 Sharp edges

12:24 Round edges

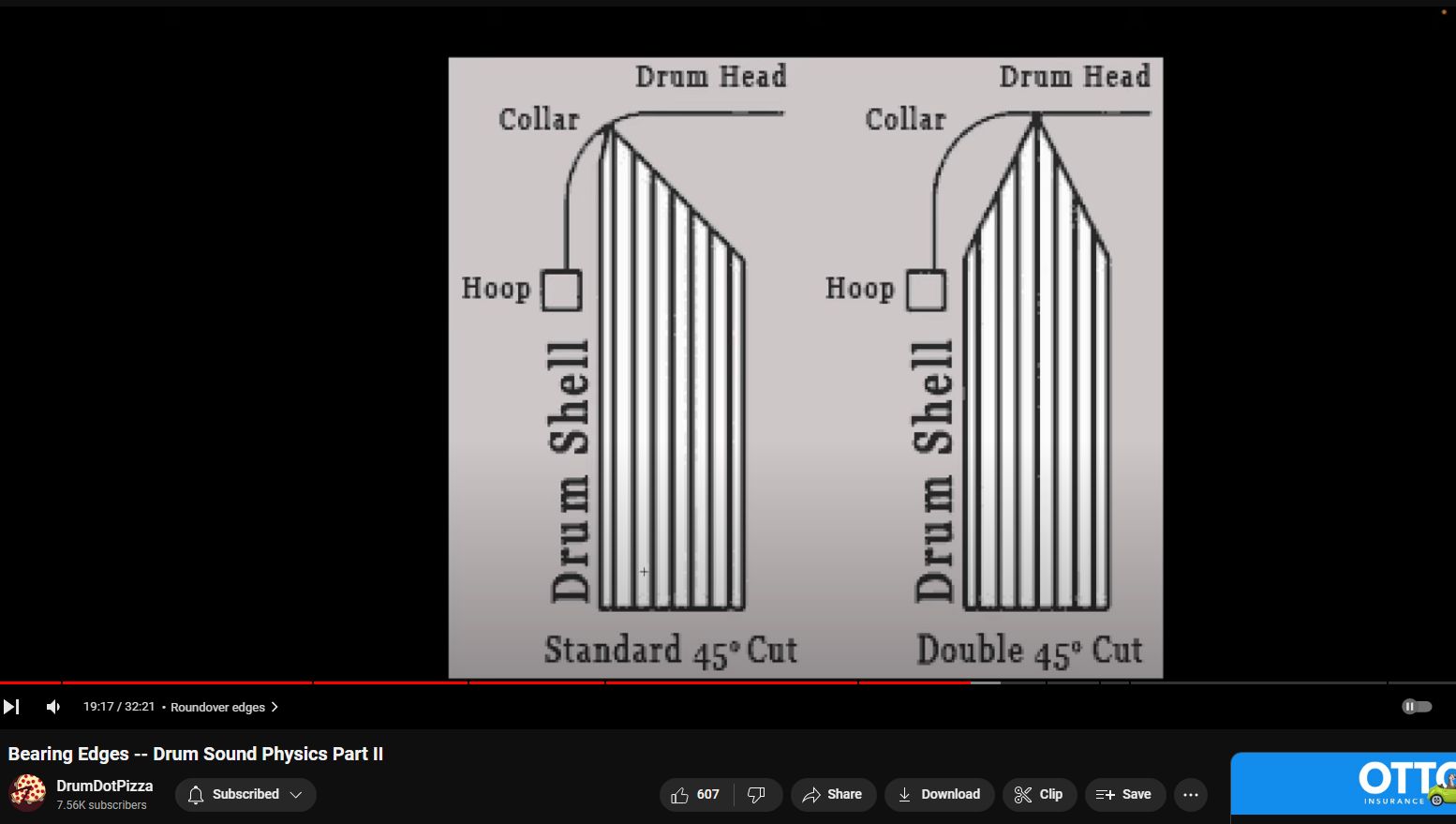

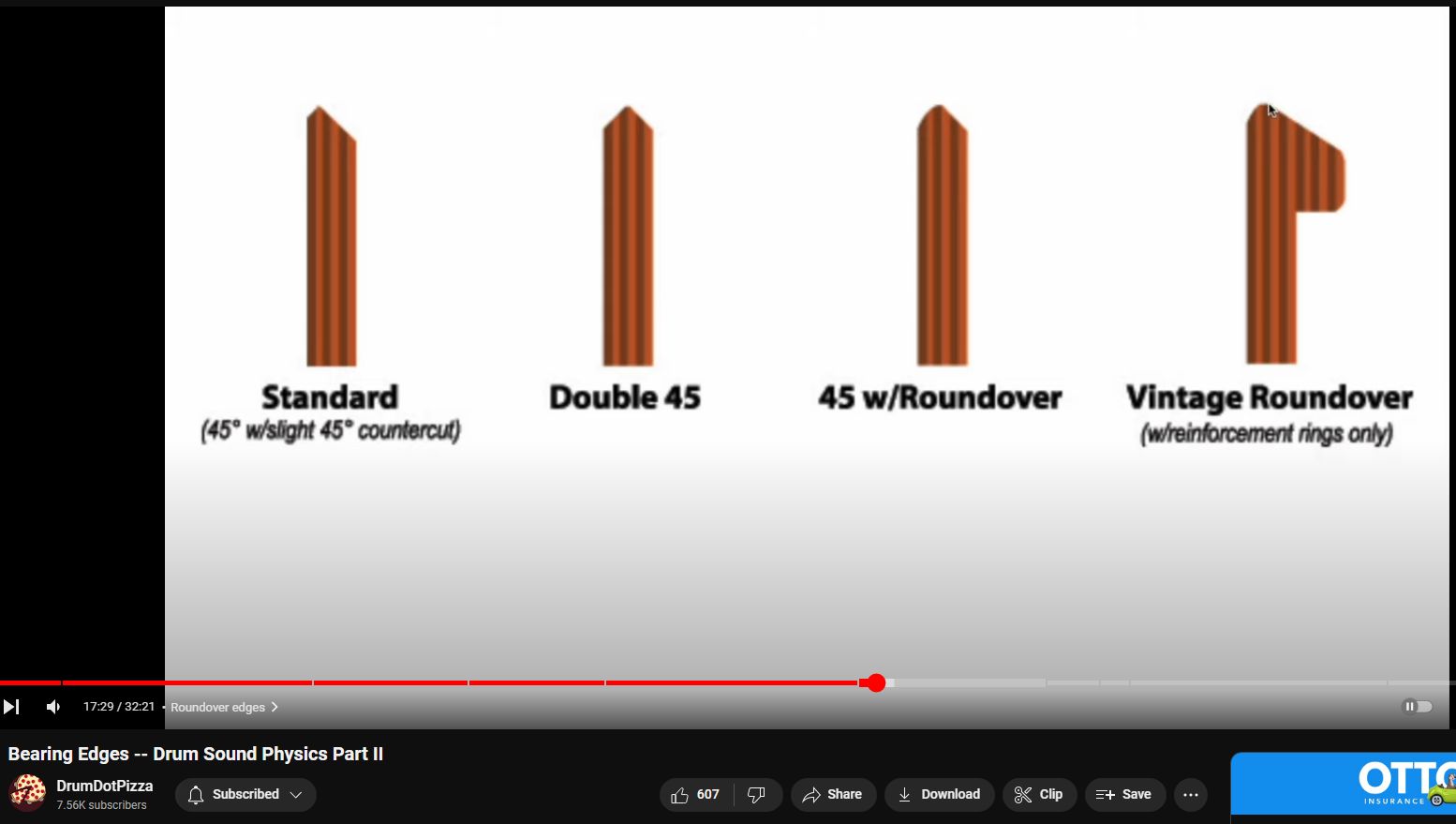

17:10 Roundover edges

20:43 Single cut edges

21:41 Dual/counter cuts

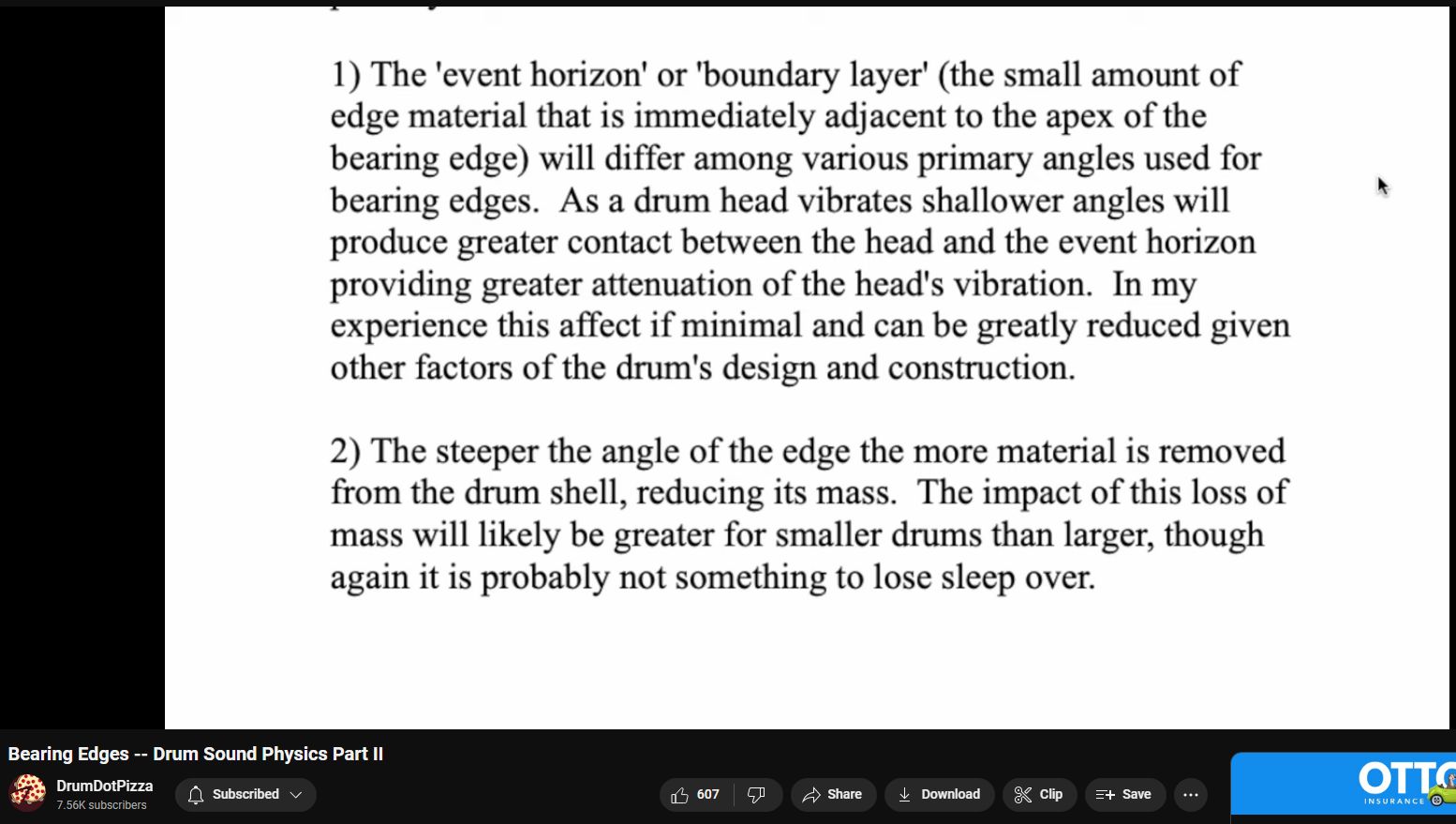

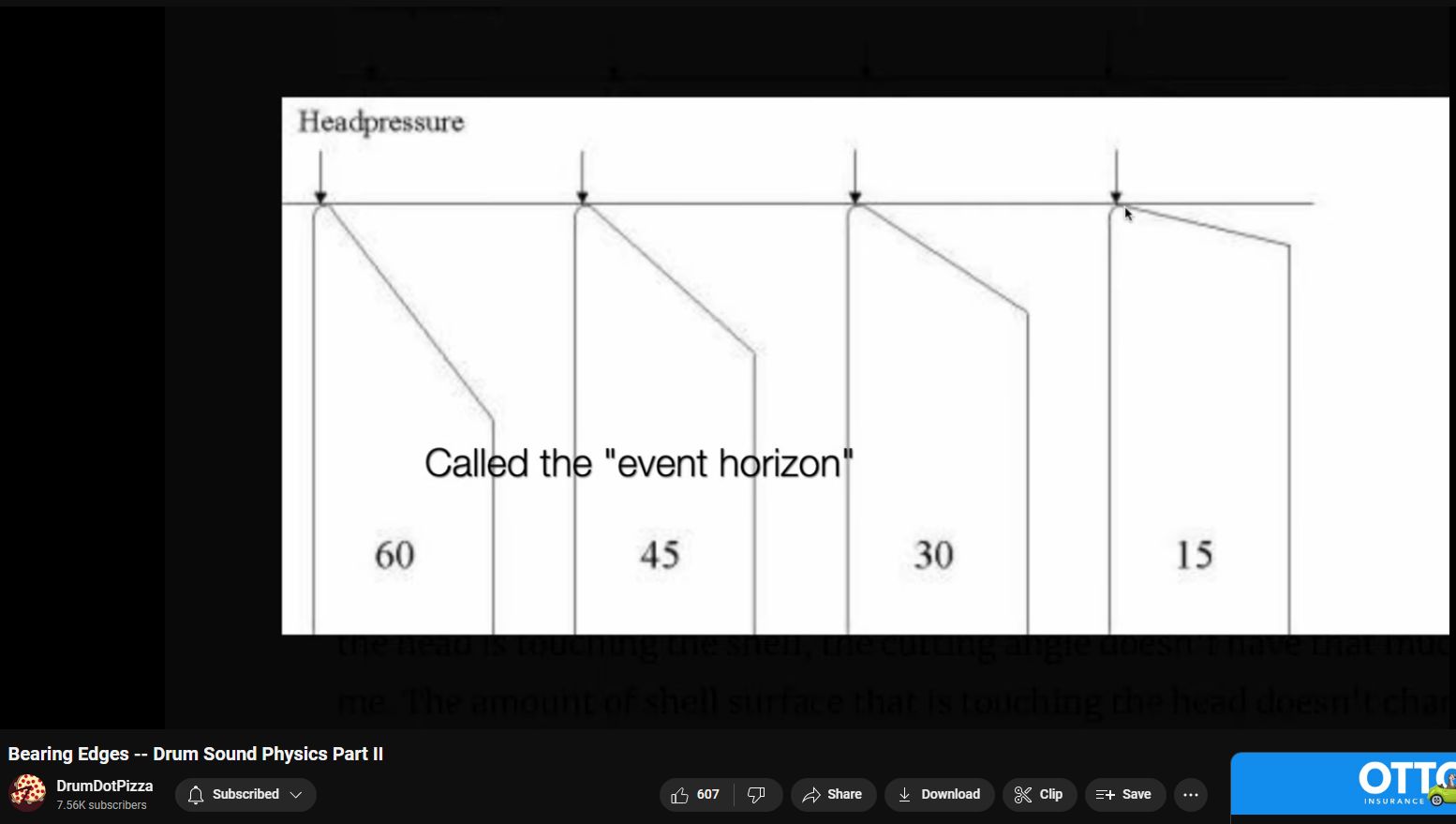

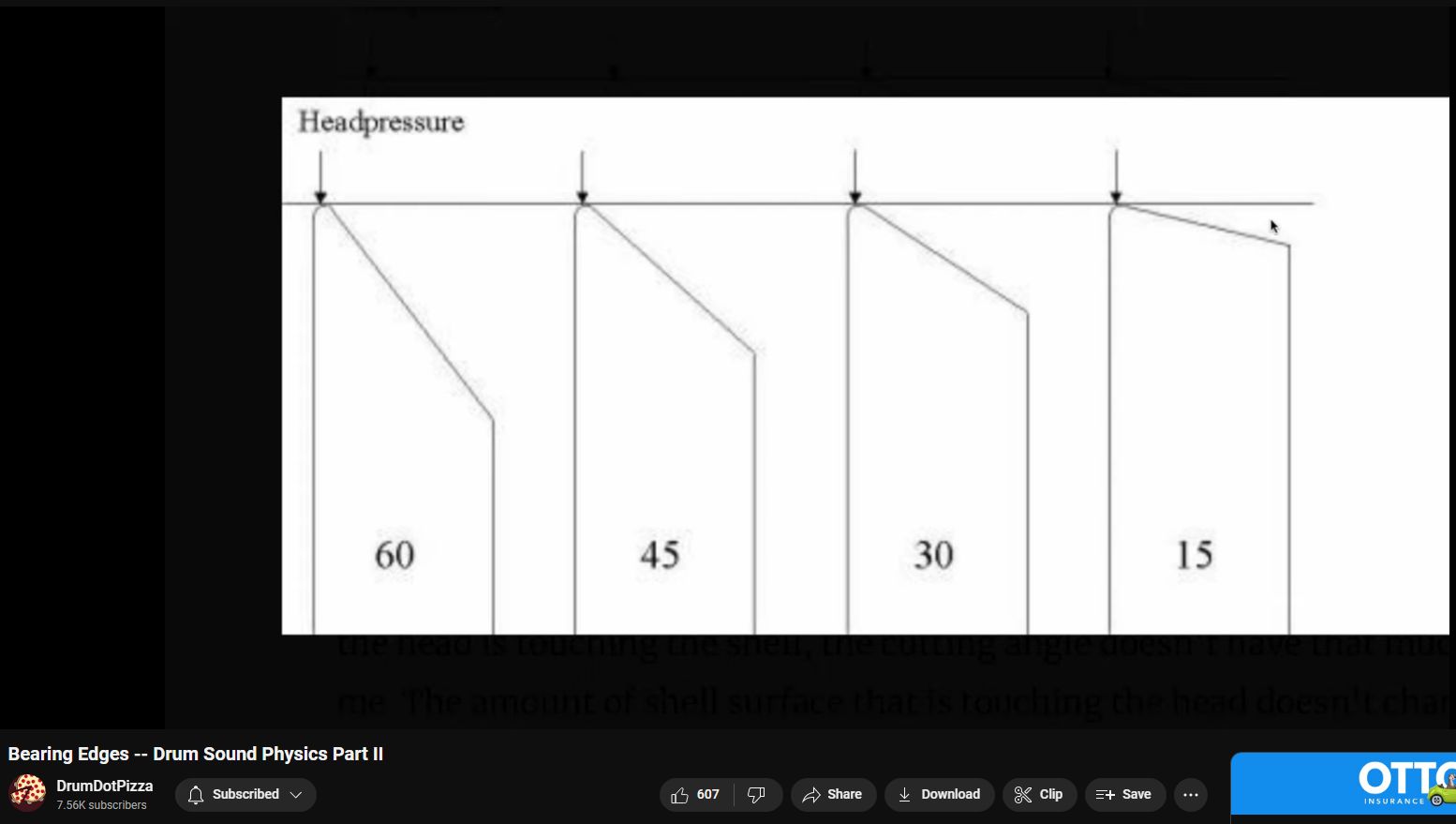

22:13 Effect of edge angle on ‘event horizon’

27:05 Effect of edge angle on drum shell mass

28:53 Conclusion

Part One of this series (dealing with mass of a drum shell):

Mike Mangini drums in ultra slow motion: (~4:24 in)

Bearing edges play a crucial role in determining the sound characteristics of a drum. They are the part of the drum shell where the drumhead comes into contact with the shell, and they influence how the drumhead vibrates and resonates. The shape, angle, and finish of the bearing edges can all impact the sound produced by the drum. Here’s how bearing edges and drum sound physics are interconnected:

1. **Shape**: The shape of the bearing edge affects how the drumhead sits on the drum shell and how it vibrates. Common bearing edge shapes include roundover, double 45-degree, and straight. Roundover edges are rounded and provide a more mellow and rounded sound. Double 45-degree edges have a sharper angle, providing more attack and projection. Straight edges are flat and provide a balanced sound with good sustain.

2. **Angle**: The angle of the bearing edge determines the contact between the drumhead and the shell. A steeper angle will result in more contact between the drumhead and the shell, which can enhance resonance and sustain. Conversely, a shallower angle will result in less contact, which may produce a more focused and articulate sound.

3. **Finish**: The finish of the bearing edge, whether it’s smooth or rough, can also impact the sound of the drum. A smooth finish allows the drumhead to vibrate more freely, resulting in a fuller and more resonant sound. A rough finish can dampen vibrations and produce a drier and more focused sound.

4. **Material**: The material of the drum shell itself can also influence the sound produced by the drum. Different materials, such as wood, metal, or composite materials, have different acoustic properties that can affect resonance, tone, and projection.

5. **Interaction with Drumhead**: The bearing edge interacts directly with the drumhead, affecting its tension and how it vibrates. The tension of the drumhead, in turn, influences the pitch, sustain, and resonance of the drum.

In summary, bearing edges are a critical component of drum construction that significantly influence the sound characteristics of the drum. By understanding the physics of how bearing edges interact with drumheads, drum makers and musicians can tailor the sound of the drum to suit their preferences and musical styles.